Maintenance of vacuum oven and vacuum pump

In the normal use of the vacuum oven, many people will not notice the vacuum pump used for the vacuum oven, and it needs regular maintenance. The main reason is that it can make the vacuum pumping effect better and increase the service life of the vacuum pump. The following describes the knowledge and maintenance of 2XZ series vacuum pump.

1、 Product introduction of 2XZ rotary vane vacuum pump for vacuum oven:

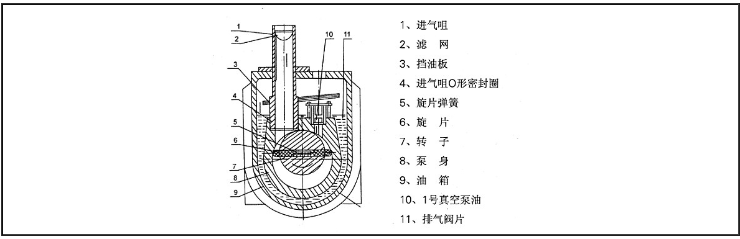

2XZ rotary vane vacuum pump is a two-stage high-speed direct connected rotary vane vacuum pump. It has a rotor eccentrically installed in the pump cavity and a rotor blade in the rotor groove. When the rotor drives the rotor to rotate, the rotor is close to the cavity wall, separating the inlet and exhaust ports, and periodically expanding the volume of the inlet cavity to absorb air. The volume of the exhaust cavity is periodically reduced to compress the gas, pushing the exhaust valve to exhaust, so as to obtain vacuum. Fig. 1 is a schematic diagram of the working principle of a single-stage pump. Two stages are two single stages connected in series.

The 2XZ rotary vane vacuum pump is equipped with an air ballast valve, which can prolong the service time of the pump oil and prevent the pump oil from mixing with water.

2XZ rotary vane vacuum pump has the advantages of small volume, light weight, low noise and convenient starting. In addition, there are measures to prevent oil return (2xz-8) and no measures to prevent oil leakage from polluting the site.

1. 2XZ rotary vane vacuum pump is the basic equipment to obtain vacuum. It can be used alone, and can also be used as the front stage pump and pre pumping pump of various high vacuum systems.

2. The air inlet of the pump shall be continuously open to the atmosphere for no more than three minutes.

3. The pump is not suitable for pumping out gases that are corrosive to metals, chemically reactive to pump oil and contain particles and dust, and explosive gases with high oxygen content.

4. The pump can be used as a compression pump or a delivery pump.

5. The working environment of the pump: the temperature is within the range of 5 ℃ - 40 ℃, the relative temperature is not more than 90%, and the inlet pressure is less than 1333pa. Long term continuous operation is allowed.

6. When installing the power supply, the wiring shall be carried out according to the provisions of the motor label, and the rotation direction of the motor shall be consistent with the arrow direction on the support.

7. The diameter of the pipeline of the continuously pumped vessel shall not be less than the diameter of the air inlet of the pump, and the pipeline shall be short and have fewer elbows. Meanwhile, pay attention to the leakage of the pipeline.

8. Check the oil level before starting each time. It is appropriate to fill the oil to 4 / 5 of the diameter of the oil indicator glass when the pump is stopped.

9. Clean sy1634-70 No. 1 vacuum pump oil is used as the pump oil.

10. The 2XZ rotary vane vacuum pump can be started at one time under the condition of atmospheric or any vacuum degree. If the XZ-1 single-stage pump is difficult to start, it can be started by removing the intake pipe plug cap and then put into operation.

2、 Structure diagram of 2XZ rotary vane vacuum pump for vacuum oven:

3、 Parameter performance of 2XZ rotary vane vacuum pump for vacuum oven:

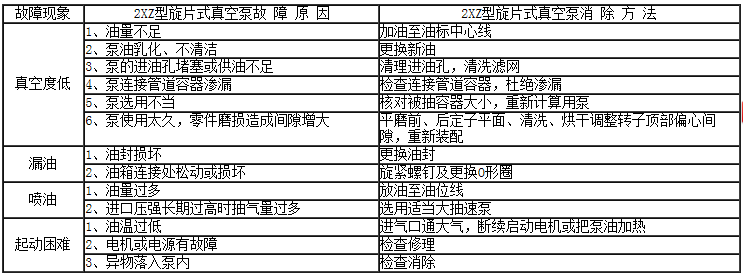

4、 Fault and elimination method of 2XZ rotary vane vacuum pump for vacuum oven:

1. The limit vacuum of 2XZ rotary vane vacuum pump is not high and its elimination

(1) The oil level is too low and there is a loud exhaust sound. Clean vacuum pump oil can be added.

(2) The pump oil is polluted by condensable steam, and can be purified or replaced with new oil.

(3) The external pipes, vessels, test instrument pipes and joints of the 2XZ rotary vane vacuum pump have air leakage. In case of large leakage, there is a loud exhaust sound and air is discharged from the exhaust port. The leakage position shall be found and eliminated.

(4) The rubber sealing diagram of air inlet nozzle or air ballast valve is improperly assembled, damaged or aging, and should be adjusted or replaced.

(5) The oil hole of the oil inlet nozzle of the 2XZ rotary vane vacuum pump is blocked. The oil inlet nozzle can be pulled out to dredge the oil hole.

(6) The vacuum system is seriously polluted, including vessels and pipes, which should be cleaned.

(7) The rotary vane spring of 2XZ rotary vane vacuum pump is broken and should be replaced.

(8) If the rotor, pump body or pump cover is worn and the clearance is too large, it shall be inspected, repaired or replaced.

(9) If the pump temperature is too high, the ventilation and cooling shall be improved. If the temperature of the pumped gas is too high, it should be cooled before entering the pump.

2. 2XZ rotary vane vacuum pump fuel injection

(1) If the oil level is too high, excess oil can be injected and discharged.

(2) Pump oil or sundries in the mist eliminator shall be removed.

3. Oil leakage of 2XZ rotary vane vacuum pump

(1) Oil drain plug, oil tank gasket or improper assembly, screw tightening;

(2) The oil mark is not tightened, and the plexiglass is overheated and deformed;

(3) The gasket of the connecting pad between the components of the 2XZ rotary vane vacuum pump body and the support is not well padded; Improper assembly or wear of oil seal; It should be adjusted or replaced.

4. Noise of 2XZ rotary vane vacuum pump

(1) The spiral spring is broken, and the spring can be replaced.

(2) If there is burr, dirt or deformation, and the operation is blocked, it shall be inspected, polished and cleaned.

(3) The bearing is worn and the parts are worn. It shall be repaired or replaced.

(4) If the motor is faulty, check it.

5. Oil return of 2XZ rotary vane vacuum pump

(1) If the check valve is not closed properly, the oil level will drop quickly after the pump is stopped. It can be opened and stopped again, and the change can be observed or disassembled for inspection.

(2) If the oil seals in the two pump covers are improperly assembled or worn, they can be replaced.

(3) If the pump cover or pump body is not flat, it can be repaired.

(4) If the exhaust valve piece is damaged, it should be replaced.

Note: check the extreme vacuum of the pump, and the compression mercury vacuum gauge shall prevail.

5、 Precautions for 2XZ rotary vane vacuum pump used in the world test vacuum oven:

Solemnly note: the company will not be responsible for personal injury and property loss caused by operation and use in violation of the above provisions.

Direct connected vacuum pump is strictly prohibited to remove flammable, explosive and toxic gases;

The direct connected vacuum pump shall not pump out the gas that is corrosive to the metal and can react with the pump oil;

The direct connected vacuum pump shall not pump out the gas containing particulate dust and a large amount of water vapor;

The temperature of the extracted gas shall not exceed 80 ℃, and the ambient temperature shall be - 5 ℃ - 60 ℃;

Direct connected vacuum pump shall not be used as compression pump and delivery pump;

Direct connected vacuum pump shall not operate without oil;

When the pump is running, it is forbidden to block the exhaust port;

① The voltage of the direct connected vacuum pump is 192-248v, and the 50Hz socket must be grounded;

② When unplugging the power supply, be sure to hold the plug instead of the power cord;

③ Do not place heavy objects on the power line of the direct connected vacuum pump, and do not allow the power line to be squeezed;

④ Do not use damaged plugs and sockets for direct connected vacuum pumps;

⑤ Do not use wet hands to plug and unplug the power plug of the direct connected vacuum pump;

⑥ Do not plug or pull the power plug and push the switch in the place where there is gas leakage of the direct connected vacuum pump.

6、 Installation of 2XZ rotary vane vacuum pump for vacuum oven:

① When the world test 2XZ rotary vane vacuum pump is used, it should be placed horizontally in a dry, ventilated and clean place, with a space distance of more than 2cm from the periphery and no less than 5cm from the front and rear ends. When it is installed on the equipment, the normal air inlet at the shell end of the fan blade should be ensured;

② Installation on supporting machines; Remove the rubber feet under the bottom plate and connect them with st4.2 self tapping screws. If there are special installation requirements for the direct connected vacuum pump, please contact our factory;

③ The air inlet can be connected according to the thread requirements of the air inlet, or can be inserted with a leather pipe;

④ If the gas discharged by the direct connected vacuum pump has an impact on human health or the working environment, the exhaust port can be connected with a pipe to lead out to the workplace or be treated for environmental protection;

⑤ If there is special need, the solenoid valve can be installed at the inlet nozzle of the pump;

⑥ If the extracted gas contains a large amount of water vapor, too high temperature and dust, corresponding devices such as cooler and filter shall be added to the inlet pipe to avoid affecting the normal use of the pump.

7、 Troubleshooting of 2XZ rotary vane vacuum pump for vacuum oven:

8、 Maintenance of 2XZ rotary vane vacuum pump for vacuum oven:

① Keep the 2XZ rotary vane vacuum pump clean to prevent sundries from entering the pump;

② Maintain the oil level of 2XZ rotary vane vacuum pump, and do not run without oil;

③ Pay attention to the cleanliness of 2XZ rotary vane vacuum pump oil. If the pump oil becomes dirty, turbid, enters water or other volatile substances and affects the extreme vacuum, the pump oil shall be replaced in time. When replacing new oil, start the pump for 30 minutes to make the oil thin, stop the pump, drain the oil from the oil drain hole, and then open the air inlet for 1-2 minutes. During this time, a small amount of clean pump oil can be added from the air inlet to replace the oil in the pump chamber. Repeat several times, after confirming that the 2XZ rotary vane vacuum pump has been cleaned, install the oil drain plug, and then inject clean pump oil from the oil filling hole to the oil level line;

④ When it is not used for a long time, the 2XZ rotary vane vacuum pump shall be covered with inlet and exhaust caps, and placed in a dry place. Pay attention to moisture and rust prevention;

⑤ If the pump needs to be disassembled and repaired, it must be carried out by professionals with certain experience in repairing the pump, or contact the company.

Kunshan Shizhan Precision Instrument Co., Ltd ©2017 dgzhongzhi.com 版权所有

Kunshan Shizhan Precision Instrument Co., Ltd ©2017 dgzhongzhi.com 版权所有